By Katia Lucuy

Walk into any design meeting today and you’ll likely hear the word decarbonization. Among many strategies, it’s become a key focus in the building industry’s response to climate change. But what does it actually mean for the spaces we build? More importantly, how do we turn broad climate goals into specific, measurable actions, especially when much of a building’s emissions are released before the lights are ever turned on?

Buildings account for nearly 40% of global greenhouse gas emissions, and the construction sector generates an estimated 1.3 billion tons of waste annually, about one-third of the world’s total waste. Every project offers a chance to lead by example, to influence policy and practice, and to help build the sustainable, resilient future our communities deserve.

Beyond energy modeling and solar panels, a new layer of opportunity is emerging. It’s the carbon hidden in plain sight: the emissions embedded in concrete slabs, steel frames, ceiling tiles and gypsum board. This is embodied carbon, and it’s rapidly becoming one of the most critical dimensions of sustainable design.

At the same time, frameworks like LEED v5, along with public-sector policies such as New York State’s Executive Order 22 and New York City’s Executive Order 23, are turning embodied carbon from a “nice to have” into a non-negotiable. As regulations evolve and emissions from operations decline, material selections are taking center stage. Understanding embodied carbon is no longer optional, it’s essential.

Embodied vs. Operational: Two Sides of Decarbonization

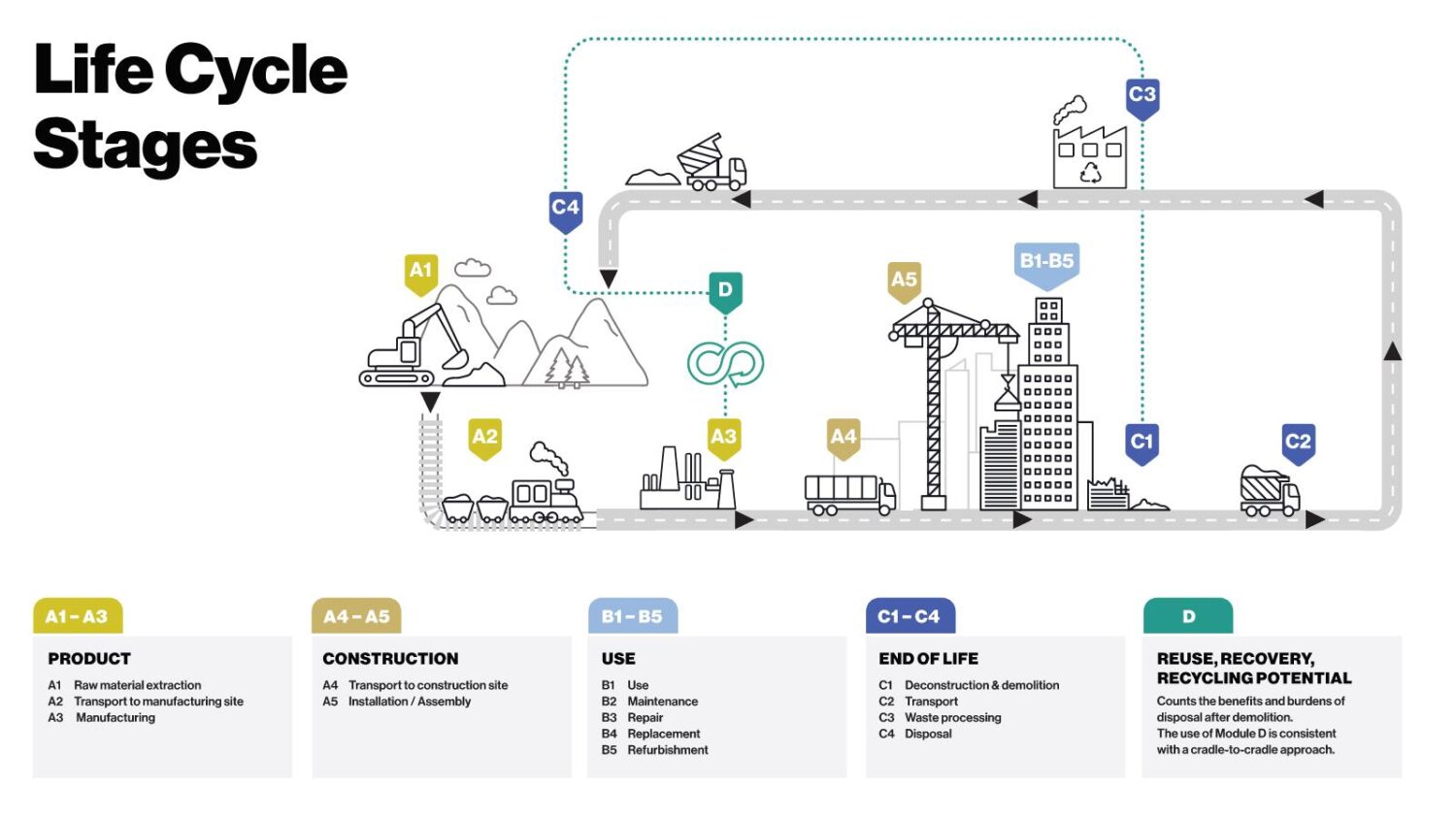

Decarbonization in the built environment means reducing greenhouse gas emissions across a building’s entire life cycle. This includes:

- Operational carbon: Emissions from heating, cooling, lighting and powering the building. These are ongoing and largely influenced by the local energy grid. As grids transition to cleaner, renewable energy sources, operational emissions are expected to decline.

- Embodied carbon: Emissions associated with the extraction, manufacturing, transportation, installation, maintenance, and end-of-life stage of building materials. Unlike operational carbon, these emissions are released upfront, becoming locked in as soon as construction begins.

Cities like Denver, Boston, Washington D.C., and New York are implementing progressive regulations (such as NYC Local Law 97) to cap operational emissions and encourage more efficient buildings. In parallel, significant investments are being made to decarbonize the energy grid itself, accelerating the reduction of operational impacts.

But as operational emissions decrease, embodied carbon is emerging as the dominant source, especially in newer, high-performance buildings. According to the Carbon Leadership Forum’s California Carbon Report, embodied carbon can account for over 60% of a building’s total emissions over a 60-year lifespan in certain typologies. This underscores the urgency of addressing embodied impacts early in the design process, when material choices and construction methods still offer the greatest potential for carbon savings.

The Stages of Embodied Carbon

Let’s take a moment to follow the journey of a quiet, unglamorous and often overlooked character in the built environment: a humble gypsum board panel. It’s not flashy like the curtain wall or smart like the HVAC system, but its story is rich, and it has a carbon footprint to prove it.

Our panel’s life begins underground, as a mineral resting in ancient rock formations. One day, machines awaken it. It’s mined, crushed, baked and shaped into the smooth, rigid board we know so well. This early transformation, spanning raw material extraction to manufacturing, is known as Stage A1 to A3, or the Product Stage. It’s where most of the material’s embodied carbon is born, long before it ever sees a building site.

Next comes the journey. Loaded into a truck or ship, our panel travels across highways and oceans to reach its construction site. This is Stage A4, the Transport Stage. Upon arrival, it’s unpacked, hoisted, cut and fixed into place by a crew of workers. These on-site activities make up Stage A5, the Installation Stage. Just like that, our panel has become part of a wall, one of thousands forming the shape and spirit of a building.

Then come the silent years. In the glow of office lights or the hum of a classroom, the panel simply exists, holding space, muffling sound, catching the occasional scuff. This is the Use Phase, spanning Stages B1 to B7, covering everything from routine cleaning to major renovations. The panel may be patched, painted or even replaced. And every material swap or repair quietly adds more carbon to the building’s bill.

Eventually, all buildings meet their end of life. The walls are torn down, and our panel is ripped from the structure it helped define. Stages C1 to C4, End-of-Life, follow. If the panel is landfilled, its story closes with a thud of finality. But sometimes, just sometimes, there’s a twist in the tale.

Enter Stage D, the “what if?” of carbon accounting. If the panel is salvaged, recycled, or its materials reused in future buildings, it earns a kind of environmental afterlife. This stage captures the emissions avoided because something didn’t have to be made from scratch again.

It’s a rare reward called Module D and it’s only possible when circular thinking and careful design come together.

This is the carbon story of a material from its birth to its potential rebirth. Each stage leaves a mark. Each decision along the way – what we extract, how we build, what we throw away – contributes to a building’s embodied carbon. And while it’s easy to admire the high-tech or high-design elements of a project, the real environmental impact is often hidden in plain sight. In every ceiling tile, carpet pad or wallboard, a carbon legacy is quietly taking shape.

By understanding this life cycle, we gain something powerful: the ability to intervene. To question. To choose differently. And to reshape that legacy, one material at a time.

Life Cycle Analysis

If embodied carbon tells the story of a material’s environmental impact, then Life Cycle Assessment (LCA) is the lens that allows us to read it clearly.

An LCA is a systematic method for evaluating the environmental effects of a product, material, or building over its entire life. In the context of architecture and construction, it’s how we measure the carbon cost of our decisions: from the moment raw materials are extracted, through manufacturing, delivery, installation, maintenance and eventually disposal or reuse.

Think of it as a forensic audit of emissions, tracking every stage of a building material’s life. LCAs assign emissions to specific stages using standardized frameworks, so we can compare materials, systems or even entire buildings on an equal footing.

But while LCAs are powerful, they aren’t all-seeing. A typical embodied carbon study will focus on what’s called the “core and shell” or “base building” scope: structure, envelope and essential systems. Some studies go further, including finishes or built-in furniture. Fewer still extend to tenant upgrades, the elements most often swapped out every 8-15 years, like carpeting, lighting fixtures or demountable walls. And personal furnishings? Usually left out entirely.

Why does this matter? Because the carbon we don’t count is still carbon. That sleek new lounge chair or tech wall might not show up in your LCA report, but still required materials, manufacturing and transport. The more we broaden the scope of what we measure, the more accurate our understanding becomes and the more effective our decarbonization strategies can be.

LCA is both a science and an evolving practice. It’s only as good as the data that feeds it, and the boundaries we set when asking the question. But even with its imperfections, it remains the most powerful tool we have to measure embodied carbon and start holding it accountable.

Every building tells a story. And behind every tile, panel, and beam is a choice, one that shapes our collective future. As we face the climate crisis, decarbonization offers a path not just to reduce harm, but to reimagine what’s possible. In the coming articles, we’ll dive into the tools and knowledge that help turn intention into action. The future is still under construction. Let’s build it with care.